Waylead Two-Axis Robot Automated Case Packer

2026-02-27

Two-Axis Robot Automated Case Packer As a professional provider of intelligent packaging solutions, Waylead is proud to launch our high-performance, specially designed for large-scale food processing plants, beverage factories, canning production lines and high-output manufacturing facilities. This ...

View More

Robot Palletizing System Empowers Enterprises to Upgrade Efficiently

2026-02-11

Robot Palletizing System As a key link connecting production and logistics, palletizing efficiency and stability directly determine the turnover speed of an enterprise’s supply chain. However, the pain points of traditional manual palletizing have long restricted enterprise upgrading: high-intensity ...

View More

Core Equipment and Application Scope of Automatic Food Packaging Lines

2026-02-08

Automatic food packaging lines are core equipment for food processing, achieving full automation from material pretreatment to finished product packaging. Core equipment, modularly configured by process, includes three categories: Pre-processing equipment: material sorters, weighing/filling machines...

View More

Automatic Combination Checkweigher Metal Detector: The Core of Efficient Food Inspection Systems

2026-01-30

Automatic Combination Checkweigher Metal Detector In the food processing industry, ensuring product safety, meeting packaging standards, and optimizing production efficiency are the keys to gaining a competitive edge. For small and medium-sized enterprises (SMEs) focused on packaging quality control...

View More

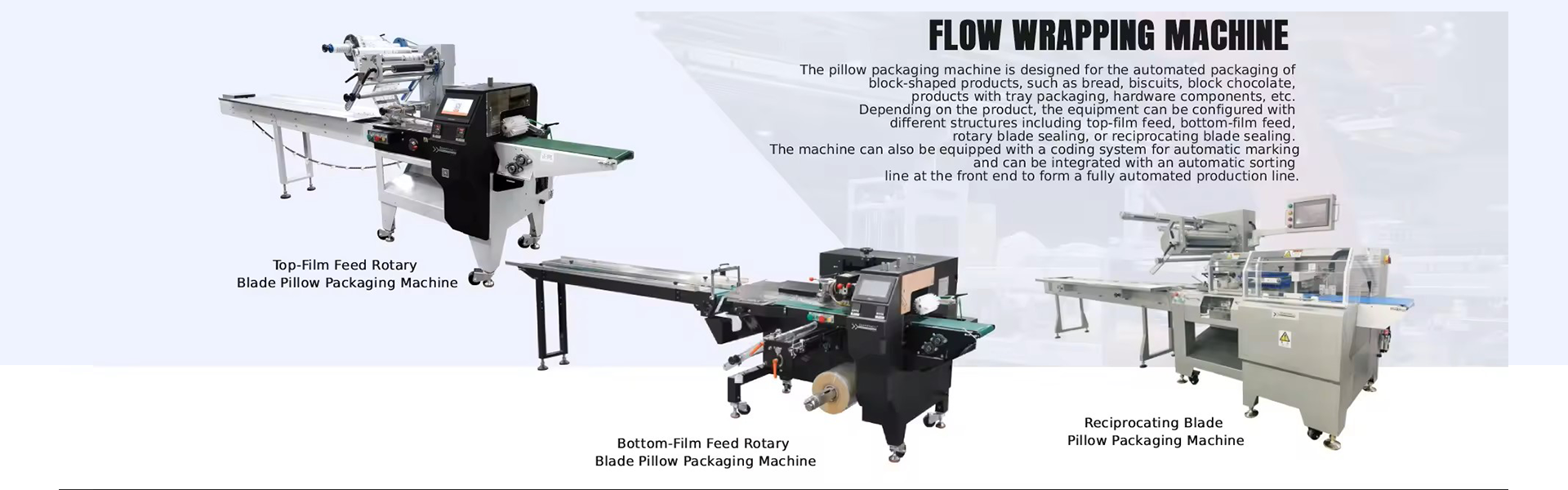

Pillow Packing Machine:Boost Bakery Productivity & Freshness for High-Volume Production

2026-01-22

Elevating Bakery Production with Our Industrial Pillow Packing Machine The Necessity of Modern Packaging For bakery businesses scaling up high-volume production, investing in a reliable Pillow Packing Machine is no longer an option—it’s a necessity to stay competitive. Our automatic industrial flow ...

View More